Production, equipment

Milling

CNC milling

Working area: 2000 x 900 x 900

3-axis (4th axis: preparation)

BLUM workpiece measuring system

Working area: 1050 x 510 x 510

4 axis production center

BLUM workpiece measuring system

Working area: 1050 x 560 x 460

4 axis production center

BLUM workpiece measuring system

Working area: 1050 x 510 x 510

3-axis

BLUM workpiece measuring system

Working area: 650 x 500 x 450

3-axis (4th axis: preparation)

BLUM workpiece measuring system

Working area: 760 x 406 x 508

3-axis

BLUM workpiece measuring system

Universal Milling

Working area: 1090 x 400 x 350

3-axis

Horizontal, vertical head, distance calculator

Working area: 600 x 300 x 250

3-axis

Horizontal, vertical head

Turning

CNC Turning

Working area: d=370 x L=950

Axis: 2 + “Y”-axis + live tool, vibration control

Options: live tool; steady rest; vibration control

Working area: D=400 × L=950

2-axis

Universal Turning

Working area: D=400 L=1500

2-axis

Working area: D=400 L=750

2-axis

Grinding

Surface grinding

Working area: 1000 x 500 x 540

with NC control

Cylindrical grinding

Working area: D=250 x L=7500

Welding

Gas-shielded welding

Drilling and tapping

Drilling and tapping

Other

Dynamic balancing

Max. 10 kg

Slotting

Working area: Lmax = 250

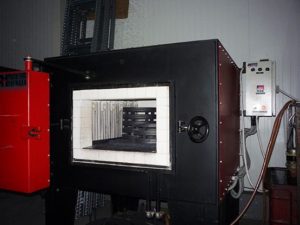

Heat treatment

Size: 800 x 500 x 300

Max. temperature: 1200 °C

- Case hardening

- Induction hardening

- Vacuum hardening

- Nitriding

Cutting

- Flame cutting

- Laser cutting

- Water jet cutting

Dispersing

Surface treatment, others

- Painting (solvent and dust painting)

- Galvanization

- Chromization

- Browning

- Anodising

- Casting

- Forged products

- Assembly